The PVC n'ala calendeing usoro bụ nke ọma na-aga n'ihu mmepụta usoro, nke kwesịrị ekwesị karịsịa maka mmepụta nke homogenous na permeable Ọdịdị Ibé akwụkwọ (dị ka azụmahịa homogeneous permeable flooring). Isi ya bụ ịkwanye PVC a wụrụ awụ ka ọ bụrụ akwa akwa edo edo site na calender ọtụtụ mpịakọta, wee mee ka ọ dị jụụ ka ọ na-akpụzi. Ihe ndị a bụ usoro ndị akọwapụtara na isi ihe njikwa teknụzụ:

I. Usoro kalenda

Ngwakọta Ngwakọta Raw> Ngwakọta ọkụ na-agba ọsọ dị elu, ntụ oyi na ịgwakọta oyi, ngwakọta ime na plastik, ngwakọta mepere emepe na nri.

Calendering mpịakọta anọ, embossing/laminating, jụrụ na ịkpụzi, trimming na winding

II. Isi isi ọrụ nzọụkwụ-site-nzọụkwụ na oke nka nka

1. Ngwakọta ihe eji eme ihe na ngwakọta

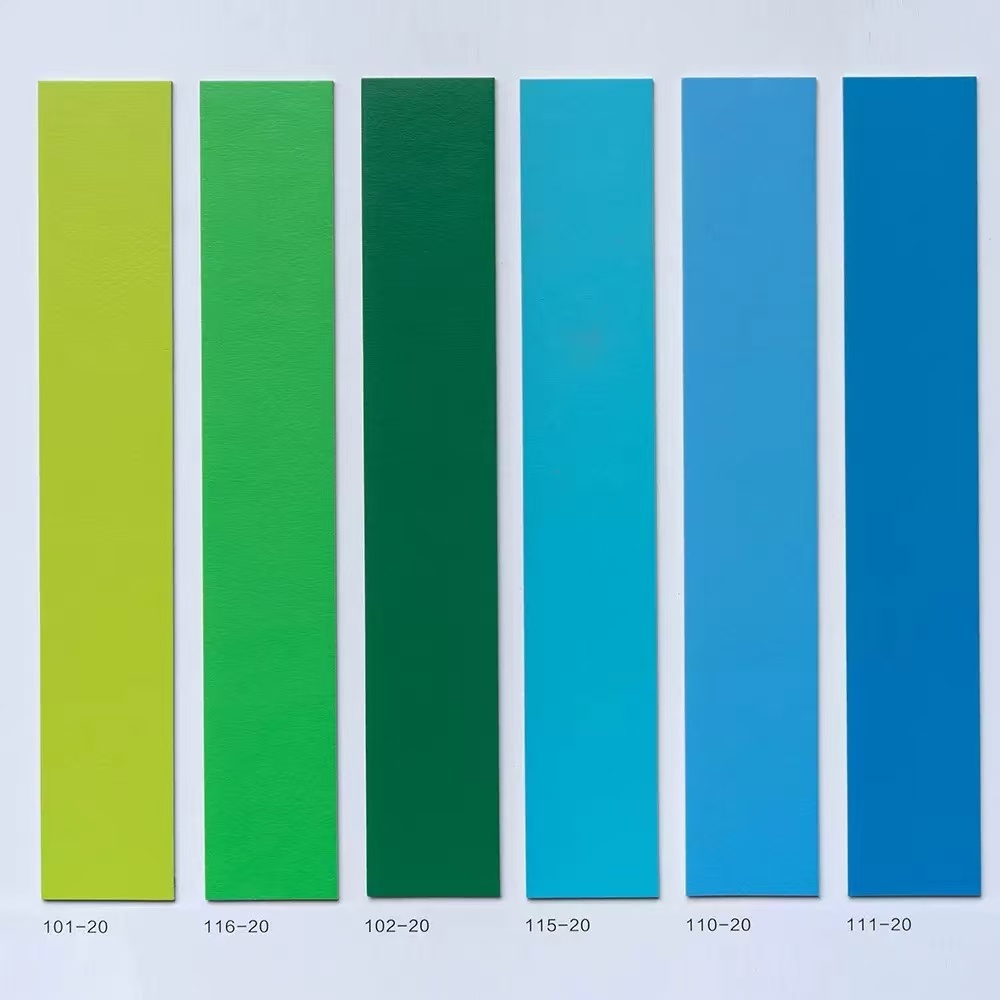

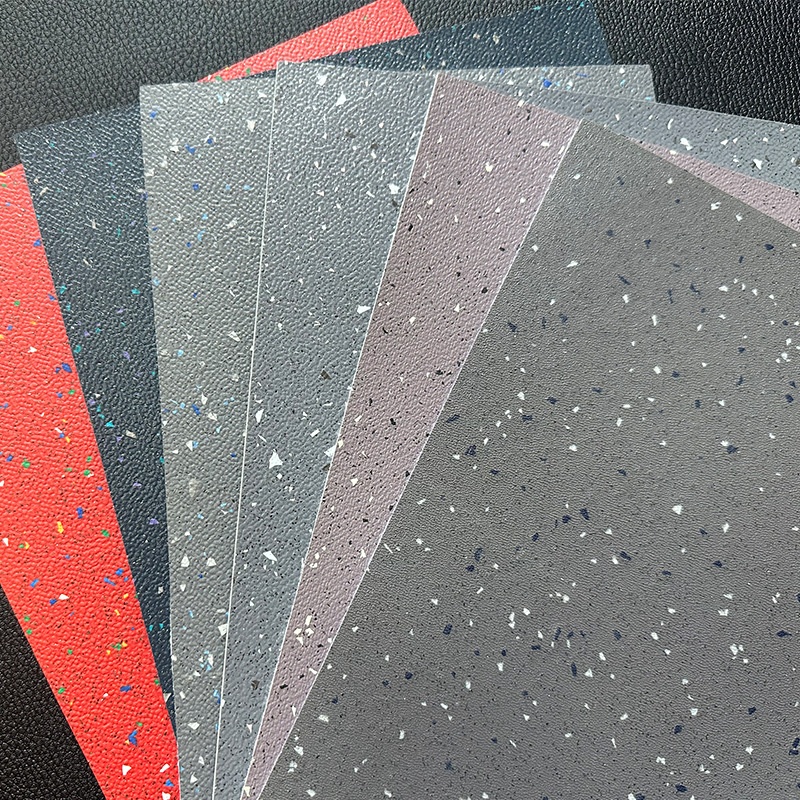

Ụdị ihe mejupụtara (Ihe atụ): - PVC resin (ụdị S-70) 100 akụkụ, - Plasticizer (DINP / gburugburu ebe obibi enyi ester) 40-60 akụkụ, - Calcium carbonate filler (1250 ntupu) 50-80 akụkụ, - Okpomọkụ stabilizer (calcium zinc composite) 3-5 akụkụ, Lubriric acid akụkụ, 3-5. - Pigmenti (titanium dioxide / inorganic agba ntụ ntụ) 2-10 akụkụ

Usoro ngwakọta *:

Ngwakọta na-ekpo ọkụ: Ngwakọta ngwa ngwa dị elu (≥1000 rpm), okpomọkụ ruo 120 ° C (nkeji 10-15) iji kwe ka PVC banye na plasticizer; Ngwakọta oyi: Ngwa ngwa dị jụụ ruo n'okpuru 40C (iji gbochie lumps), oge ngwakọta oyi ≤ 8 nkeji.

2. Plasticizing na nri

- Ngwakọta dị n'ime: Okpomọkụ 160-170 ° C, Nrụgide 12-15 MPa, Oge 4-6 nkeji → Ịmepụta nnukwu roba roba;

Mepee igwekota: okpomoku ejima-roll 165± 5°C, Roller Gap 3-5 mm → Bee n'ime ibe maka inye nri na-aga n'ihu na kalenda.

3. Kalịnda rola anọ (Usoro isi)

- Usoro isi:

- Roller Speed Ratio: 1 #: 2 #: 3 #: 4 # = 1: 1.1: 1.05: 1.0 (iji gbochie nchịkọta ihe);

- Nkwụghachi ụgwọ n'etiti ịdị elu: Roller 2 ejiri okpueze 0.02-0.05mm mebie nrụrụ mgbada ọkụ. 4. Ngwọta Elu na Lamination

Embossing: Embossing roller (silicone / steel) okpomọkụ 140-150 ° C, nrụgide 0.5-1.0 MPa, ọsọ dabara na akara calendering;

Mgbochi mkpụrụ (nhọrọ): Glass fiber mat/ akwa na-abụghị nke a kpara akpa, preheated (100°C), ejiri PVC gbazee na rola #3 iji kwalite nkwụsi ike akụkụ.

5. Ntu oyi na ịkpụzi

Okpomọkụ rola jụrụ oyi nke agba atọ:

Njikwa ihe nhụsianya: esemokwu ikuku 10-15 N/mm² (iji gbochie nrụrụ oyi na nrụrụ).

6. Mbelata na ikuku

- Ntụle ịdị arọ dị n'ịntanetị nke Laser: Nzaghachi n'ezie na-edozi oghere nke rola (ezigbo ± 0.01mm);

- Mkpụcha akpaaka: obosara nke mperi ≤ 20mm, megharịa ya na pelletized maka ojiji;

- Ikuku: ikuku ikuku etiti na-adịgide adịgide, dayameta mpịakọta Φ800-1200mm. III. Usoro ihe isi ike na ngwọta

1. Ọkpụrụkpụ na-enweghị isi. Ihe kpatara: Mgbanwe okpomọkụ nke Roller> ± 2°C. Ngwọta: Njikwa okpomoku mmanụ mechiri emechi-Loop + Roller Cooling nso.

2. Gas dị n'elu. Ihe kpatara: Degassing ezughị ezu ịgwakọta. Ngwọta: Gbanyụọ igwekota nke ime (-0.08 MPa).

3. Edge mgbawa. Ihe kpatara ya: oke jụrụ oyi / oke ụjọ. Ngwọta: Belata ike jụrụ oyi n'ihu-ọgwụgwụ wee tinye mpaghara jụrụ oyi.

4. Ụkpụrụ anwụ. Ihe kpatara ya: Nrụgide ihe nrụnye na-ezuru ezughi oke. Ngwọta: Mee ka nrụgide hydraulic dị elu ruo 1.2 MPa ma hichaa elu elu Roller.

IV. Usoro emelitere nke ọma na gburugburu ebe obibi na arụmọrụ

1. Ndochi nkwụsi ike n'efu:

Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Na-agafe EN 14372 Ule Mbugharị;

2. Plasticizer na-emetụta gburugburu ebe obibi:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Na-ebelata Ecotoxicity.

3. Imegharị ihe mkpofu:

- Ntucha ihe mkpofu → Na-ejikọta ya na ihe ọhụrụ na nha nke ≤30% → Ejiri ya na mmepụta oyi akwa.

V. Calendering vs. Extrusion (ntụnyere ngwa)

Nrụpụta ngwaahịa: Ihe mejupụtara ala perforated / ọtụtụ oyi akwa, extrusion ọtụtụ oyi akwa (oyi na-eguzogide oyi + oyi akwa ụfụfụ)

Oke oke: 1.5-4.0mm (Ezizi ± 0.1mm), 3.0-8.0mm (nkenke ± 0.3mm)

Ngwucha elu: Elu gloss/nkenke embossing (nṅomi ọka osisi), ụdị Matte/Rough

Ngwa a na-ahụkarị: Ala na-adọkpụ perforated n'ụlọ ọgwụ na ụlọ nyocha, SPC interlocking flooring for home.

Nchịkọta: Isi uru nke usoro kalenda dị na "nkenke dị elu" na "nkwụsi ike dị elu"

- Uru usoro:

- njikwa okpomọkụ nke ọma → ọnụọgụ dị iche iche nke ịdị arọ <1.5%;

- In-line embossing na lamination → Nweta mmetụta ihu igwe / metal;

- Ngwaahịa dị:

Ihe mkpuchi ala PVC nwere oghere nwere nnukwu nkwụsi ike chọrọ (dịka usoro Tarkett Omnisports);

- Nhọrọ nkwalite:

- Njikwa ọgụgụ isi: AI-kwadoro mgbanwe oghere rola ike siri ike (nzaghachi nhụsianya n'ezie);

- Iweghachite ike: A na-eji mmiri na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ maka ọkụ ọkụ (na-echekwa ike 30%).

> Mara: N'ime mmepụta n'ezie, a ga-edozi okpomọkụ calendering na ngwa ngwa na-agba ọsọ dị ka usoro mmiri mmiri si dị (ndepụta agbaze MFI = 3-8g / 10min) iji zere mmebi (ntụgharị edo edo ΔYI <2).

Oge nzipu: Jul-30-2025